News

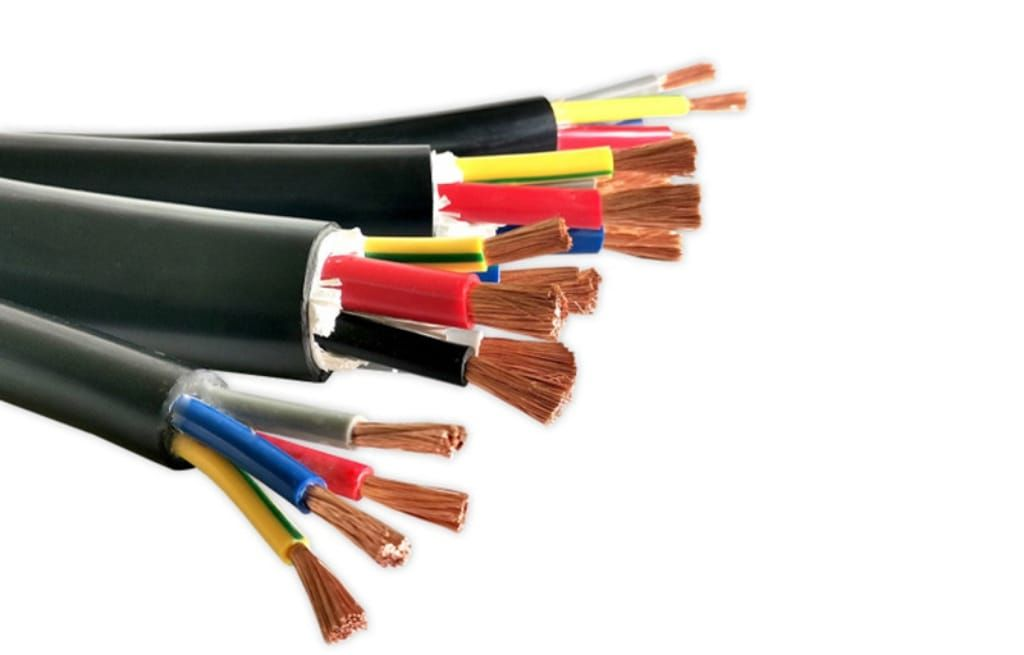

WHAT ARE THE CAUSES OF DISCONNECTION AND BROKEN GLUE IN THE PLASTIC LAYER OF WIRE AND CABLE?

Reading volume:494 Release time:2025-05-29 15:14:30

(1) There is water or oil in the conductor core

(2) The core is too heavy and the mold core is in local contact, causing the temperature to decrease, the plastic is cooled locally, and the plastic is disjointed or broken due to stretching.

(3) The quality of semi-finished products is poor, such as loose steel belts and plastic belts, joints are not strong or too large.

SOLUTION ❗ ❗ ❗

(1) The mold selection should be larger, especially the selection of the sheath mold, which should be enlarged by 6 to 8mm.

(2) Appropriately reduce the length and thickness of the mold nozzle.

(3) Reduce the speed of the screw and traction.

(4) Properly adjust the control temperature of the head.

News

Latest News

Contact Us

Tel:+86-20-31071727

Email:info@cantonu.cn

Add:Block 11,No1,Wangjiang Second Street, Nansha District, Guangzhou, China 511000.